- HOME

- ABOUT

Suzhou Zhongyima Machinery Co., Ltd (hereinafter “ZYM”) is located in the beautiful southern ancient city, Suzhou. Suzhou City is situated inside the Yangtze Delta Economic Zone, which hub is Shanghai. Suzhou City can be easy access through both international and domestic flight to Shanghai Pudong International Airport and……

- PRODUCT

-

SG Series Mesh Belt

SG Series Mesh Belt Slice Veneer drier is a new type of veneer drying equipment.

The drier integrates advanced technology from home and abroad.

Screen roller with enlarged diameter and small-pitch stainless steel make the veneer smooth and without stres -

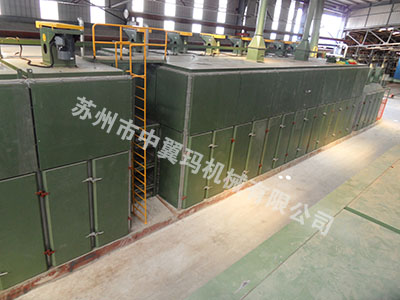

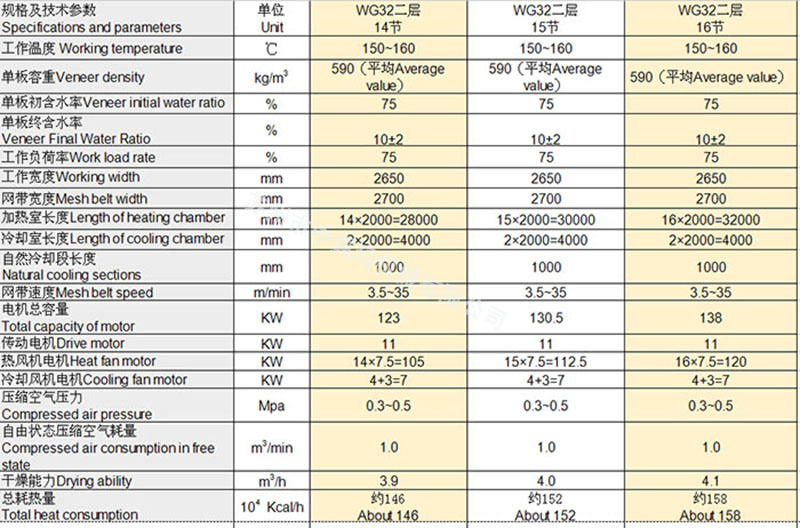

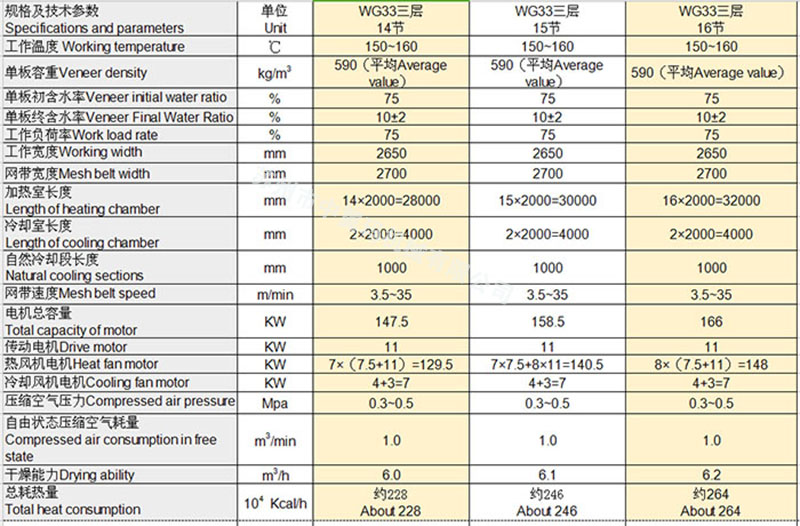

WG(J) Series Mesh Be

WG(J) Series Mesh Belt Veneer Drier which is used for face-plate,baseplate and long mid plate comprises of heating chambers and cooling chambers. This veneer drier can match with synchronous veneer feeding rack and outfeeding belt conveyer to form continu

-

TG Series Roller Ven

TG Series Roller Veneer Dryer which is specially used for drying plywood core plate comprises of heating chambers, cooling chambers, independent variable-frequency speed driving system, feeding roller table, conveyor table, wet exhaust system, microcomput

-

Accessory equipment

Accessory equipment

-

- NEWS

-

Company news

Since our establishment, Strict Quality Control Management System have always been at the core of our company. ZYM has always taken machines quality as a company priority.

-

- JOB

- SUPPORT

Since our establishment, Strict Quality Control Management System have always been at the core of our company. ZYM has always taken machines quality as a company priority. Our company has a complete set of inspection and detection measures for our machine. After Sales Team is also a strong point of ZYM, we not only provide installation, maintenance service, in the latest development, our company management has also include the consultation service in attaining plywood JAS & CARB Certificate in the team.

- CONTACT